MULTI BUS BAR TABBER and STRINGER, ZST-MBB1224

Multi Busbar:12-16BB Expandable to 24BB MAX

TABBER and STRINGER, ZSTSGT-3000

ZSTSGT3000 Series PV Welding Machine is fully automatic production machine, which can be used with different types of silicon solar cells, (monocrystalline or polycrystalline), and solder them into a string. It is suitable for 156/3BB, 4BB and 5BB and 6BB cells. Equipped with PLC, Servo, SCARA Robot, industrial image processor system, and other advanced automation technology, all processes from cell feed to string outlet are automated without manual operation. The capacity is up to 3000 cells per hour.

TABBER and STRINGER, DEMZST-800A

- ZST-800A solar Tabber&Stringer machine is compatible with soldering of cut cell and full

- Can solder solar cells with width of 31.2mm. It is the most stable and fastest stringer in the market.

- With multiple temperature zones, slow warming and slow cooling reduce rate of

- Ribbon automatic bending function, which is able to reduce cells breakage caused by distance between

- Adopts the most popular non-contact infrared light soldering method, which ensures cell and ribbon be uniformly heated to reduce the rate of

- Fine-tuning function, which is easy and timesaving to switch between 3, 4, 5 and 6 bus Switch between different width cells with same bus bar within 30 minutes.

AUTOMATIC SOLAR CELL STRINGER TABBER MACHINE, DEMZST H1300

Connecting and/or Bussing the cells strings with automated soldering process;

– Soldering capacity: ≥1300 / 2600 / 3000 cells/hour;

– Suitable for 5”, 6” square cell

– Change from 3 to 4 to 5 to 6 Bus Bar cell in less than 30 mins,

– Cell thickness: From 160 micron and up;

– Special design for the cut cells.

– Flexible value adjustment on the touch screen.

– Change cell’s width in less than 20 mins.

– High flexibility for varied cells.

– Very low maintenance.

– Only one operator for three machines.

AUTOMATIC SOLAR CELL STRINGER TABBER MACHINE, DEMZSTH530

Connecting and/or Bussing the cells strings with automated soldering process;

– Soldering capacity: ≥500 cells/hour;

– Suitable for 5”, 6” square cell

– Change from 3 to 4 to 5 to 6 Bus Bar cell in less than 30 mins,

– Cell thickness: From 160 micron and up;

– Special design for the cut cells.

– Flexible value adjustment on the touch screen.

– Change cell’s width in less than 20 mins.

– High flexibility for varied cells.

– Very low maintenance.

– Only one operator for three machines.

AUTO LAY UP MACHINE, DEMZSTD100

– Customize Auto Lay Up Machine According to Auto Tabber Stringer Seed,

– Capacity ; ≥240 cluster/h

– String localization accuracy; ±0.3mm

– Adjustable String Number between 4~12 cluster

– Adjustable String Spacing 1~10mm

– Manual + Auto – Mode, Touch Screen, Easy Operation

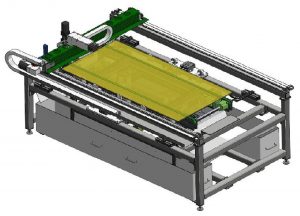

LAMINATOR, DEMZSTAYB-2222/2236/2245

Full Aotomatic Laminator :The photovoltaic module laminators are designed for different size of lamination of crystalline & poly crystalline cells with high productivity and be used for big & special applications. The machines are suitable for both standard & fast cure EVA for encapsulation of PV cells.

They are with user friendly touch screen panel to program cycle operation, controller to maintain uniform temperature and proper cooling system.

They can run in automatic mode and manual mode.

AUTOMATIC DOUBLE CHAMBER LAMINATOR, DEMZST-AYZ-2236D

DOUBLE LAYER DOUBLE CHAMBER LAMINATOR, DEMZST-AYZ2236DLDC

MAXIMUM CAPACITY with LIMITED SPACES

4th GENERATION INTELLIGENT LAMINATOR with LIFTING PIN,

DEMZST-AYZ2222P / 2236P

High Efficiency, Absolute Bubble Free, 8 Min Lamination Time

ON LINE EVA/TPT LAY UP MACHINE, ZST-EVATPT-1/2

EVA/TPT CUTTER, DEMZST-EVATPT AND AUTOMATIC EVA/TPT CUTTER ,DEMZST-HB

EVA and Backsheet needs cutting to size and uniformity. The station is a strong steel table with tough top for cutting EVA and TPT before laminating.

The station table has storage cabinets for different use and application.

SOLAR CELL TESTER, DEMZST-SCTB

The Cell Sorter Machine to sort photovoltaic cells according to their electrical performance, tested under simulated sunlight.

SOLAR SIMULATOR, DEMZST-SMTB

For measuring I-V characteristic of large size PV module made of crystalline or polycrystalline cells.

AUTO TRIMMER MACHINE, DEMZST-AutoTRIM10

EL TESTER, DEMZST-EL1600 and ON LINE EL TESTER, DEMZST–EL1600ON

Detecting breakage and defects in cells and soldering, asymmetric resistance.

AUTOMATIC FRAMING MACHINE, DEMZSTZKJ-3

The machine is suitable to use for preparing and finishing solar panel frame and lock the four corner of the frame.

PV RIBBON FORMING MACHINE, DEMZST-LF

This equipment is designed by the company independent research and development, mainly for the bending of solar dedicated bus bar.It has becoming our domestic’s First and solving the bus bar forming processing in pioneering work way.

AUTOMATIC RIBBON CUTTING MACHINE, DEMZSTRCM-5

Tinned copper strip cutting machine.Greatly enhance the processing efficiency and to reduce the interconnection of the cutting waste.

AUTOMATIC MODULE CURING LINE

Equipment Function: Stack the modules on the curing line after positioning and aligning. Place the modules onto the production line automatically after curing.

AUTOMATIC MODULE SORTING LINE

Machine consists of module P&P handler, module ports and turnover port.

Single handler for 1 – 4 trays; Double handlers for 5- 8 trays; Tray QTY can be customized; Compatible for both G-B & G-G module

Full automation with accurate and smooth operation requiring no operator; Electricity and air failure protection.

LASER SCRIBING MACHINE, DEMZST-SFS50 / SFS20

-Cutting and engraving of mono-crystalline and poly-crystalline silicon at solar industry, of non-crystal silicon with solar cell chip and wafer,

-Engraving and lineation of crystal less silicon cell board at solar energy industry,

-Cutting and lineation of silicon, germanium, gallium arsenide semiconductor substrate materials at electronic industry.

GLASS WASHING MACHINE, DEMZST-BX1500

– Horizontal structure which is used to clean the flat glass with the thickness of 3 ~12mm.

– The flat glass is placed on the transmission roller and then into the feeding part, cleaning part, drying part and last goes out.

– You can realize optional transmission speed adjustment according to the work requirement.

– The temperature of the drying air can be adjusted according to your need in advance.

– The operation buttons are concentrated on the control panel with the feature of easy operation

VISUAL MIRROR CHECK TABLE, DEMZST-GCJ

Inspection of laminating properties and appearance of the panel

SEMI ASSEMBLED MODUL CARS, DEMZZC-01/02/03

Performance characteristics:

1. Pressure from car components to be working jointly assembled steel welding and pouches.

2. 10 sets thawed the question can be placed pressure on disposable components.

3. Plastic trays were placed components and steel components will be separated in order to avoid a collision damaged components such as scratches and unforeseen circumstances.

4. Armed with the universal roller rotational flexibility to ensure the smooth flow of vehicles arrived at the designated location.

Please contact us for our customised cost effective solutions for your PV Production Lines Project